We utilize a wide variety of compounds designed to meet your specific requirements such as biocompatibility needs, radiopaque loadings, and preferred sterilization methods. We can also meet your non-medical requirements for flame or low smoke needs, chemical compatibility, and temperature withstand.

Extrusion materials we commonly work with include:

- PVC

- HDPE

- Polyurethane

- Nylon

- PEBAX®

- FEP

- PFA

- ETFE

- PTFE (liners)

- PEEK

- TPE

- Grilamid®

Should you have a specialty compound you’d like us to use in your tube design, we would be happy to help! Just contact us to discuss your ideas and needs with our custom design team!

Extrusion Materials

| Material | Durometer Range | Advantages | Considerations | Examples Where Used |

|---|---|---|---|---|

| PVC | Soft (70A-90A) | *Cost effective *Flexible | *Limited sterilization *Requires specific compounds for medical use | *Unreinforced tubing *Multi-Lumen |

| HDPE | Hard (50D-70D) | *Cost effective alternatives to PTFE liners *Good chemical resistance | *Low temp limit *High flexural modulus | *Unreinforced tubing *Liners |

| Polyurethane | Very Soft - Very Hard (80A - 75D) | *Great elasticity *Softens at body temperature *Flexible *Abrasion resistant *Easily compounded with additives | *Hygroscopic *Can be tacky | *Topcoat *Tie layer *Unreinforced tubing *Reinforced tubing |

| Nylon | Hard - Very Hard (40D - 90D) | *Wear resistant *Rigid | *Hygroscopic *High flexural modulus | *Topcoat *Unreinforced tubing *Reinforced tubing |

| PEBAX® | Soft - Hard (25D - 74D) | *Widely used in Medical industry *Has great temperature stability *Relatively low coefficient of friction *Easily compounded with additives | *Cost *Softest grade is 25D | *Topcoat *Tie layer *Multi-lumen *Unreinforced tubing *Reinforced tubing |

| FEP & PFA | Hard (55D - 60D) | *Low coefficient of friction *Thin walls *Cost effective alternative to PTFE Liners | *Not suitable for gamma sterilization *Cost | *Liners *Multi-lumen *Reinforced tubing |

| ETFE | Very Hard (~75D) | *Suitable for gamma sterilization | *Rigid | *Liners |

| PEEK | Very Hard (~85D) | *Very rigid *Great chemical resistance | *Can be cost prohibitive *Opaque | *Unreinforced tubing *Multi-lumen |

| TPE | Very Soft - Soft (55A - 90A) | *Flexible *High elongation | *Low temperature rating *Limited sterilization | *Multi-lumen |

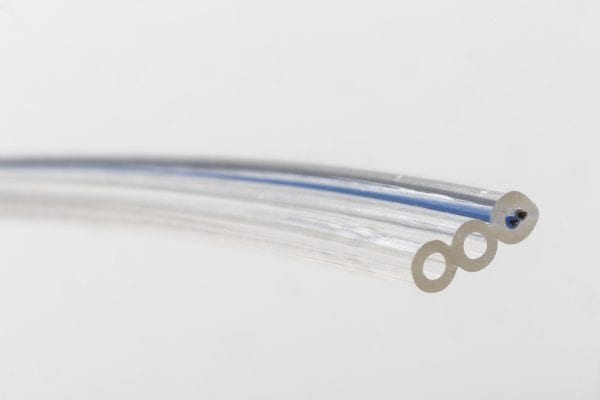

| Grilamid® | Hard | *Very optically clear | *Best used where high rigidity and high optical clarity are required | *Unreinforced tubing *Multi-lumen |

Note: Durometer values given in shore scale