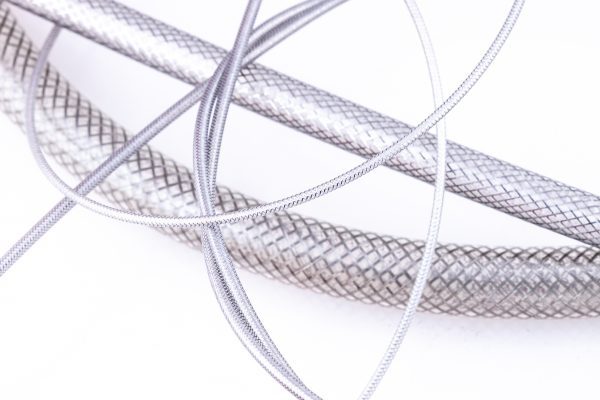

We’d love to show you around the Testing Lab here at New England Tubing. We utilize state-of-the-art equipment and instrumentation to ensure compliance and provide the highest quality products while working closely with our customers to co-develop test methods for validation programs and first article production.

As Director of Engineering, Mike Boivin states:

“The various measurement and analytical tools that NETT has to offer allows us to provide qualitative data in regards to our specialized tubing. We have the ability to measure mechanical performance of our products such as tensile, flexibility, torque and crush resistance. We also have the ability to perform analytical analysis for material identification and failure analysis using our scanning electron microscope and other analytical tools. These abilities allow NETT to provide highly engineered products with well understood performance characteristics. NETT use these analytical tools to model performance of our tubing to meet the performance needs or our customers.”

“The various measurement and analytical tools that NETT has to offer allows us to provide qualitative data in regards to our specialized tubing. We have the ability to measure mechanical performance of our products such as tensile, flexibility, torque and crush resistance. We also have the ability to perform analytical analysis for material identification and failure analysis using our scanning electron microscope and other analytical tools. These abilities allow NETT to provide highly engineered products with well understood performance characteristics. NETT use these analytical tools to model performance of our tubing to meet the performance needs or our customers.”

Let’s take a look.

For a list of some of the tests we regularly perform, click here.