Annealing – The process of heating wire and then slowly cooling it to room temperature in order to soften it.

Autoclave – Sterilization process to kill bacteria/germs that uses steam (about 275°F or 135°C).

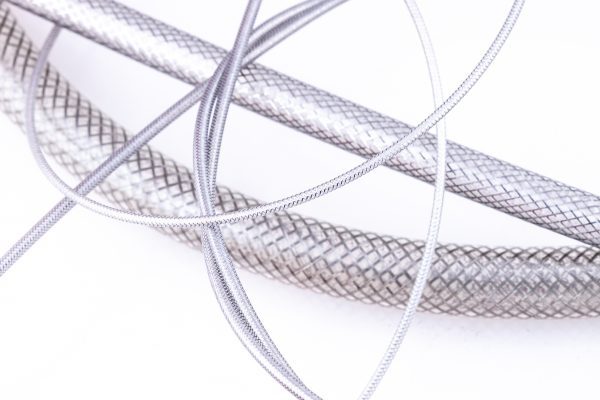

Braid angle – The acute angle formed by the braid strands and the axis of the tube.

Braid pattern – Three main types are:

- Standard Braid – The strands of one bobbin alternately cross over and under two strands. (One – over two – under two).

- Diamond pattern full load – The stands of two bobbins cross over and under two strands. (Two – over two – under two).

- Diamond pattern half load – the stands of one bobbin cross over and under one strand. (One – over one – under one).

C.E. Mark – European Community regulations requiring inspection and registration of Medical Device manufacturers who wish to sell their products in Europe (Includes most of ISO 9000 and some additional requirements).

Catheter – A tubular medical device designed to allow access to specific areas of the body via surgical or natural pathways in the body. Length is generally referenced in centimeters and diameter in French size (Fr), millimeters (mm), or inches.

Centerless grinding – Removes material from the outside surface of the tube to create a consistently smooth surface.

- Thru feed grinding– The tube is fed through the grinding wheels completely, entering on one side and exiting on the opposite.

- Infeed grinding – A method of cylindrical grinding in which the work piece is held stationary while the grinding wheel is fed into the work piece at a specified location and depth.

Clean Room – A manufacturing area that meets specific guidelines in terms of cleanliness, air flow and bioburden (background level of germs). Clean Rooms are routinely tested for particulate and bioburden levels.

Cold Sterilization – Process to kill bacteria/germs that use a liquid bactericide at room temperature.

Controlled Environment – A manufacturing area in which intentional steps are being taken to minimize and control dust and germs but routine testing is not performed (same as White Room).

Distal – The far end of a device (from the user’s viewpoint).

Durometer – One of several measures of the hardness of a material.

Endoscope – A flexible fiber optic device used to view internal areas of the body (such as the lungs, kidneys, stomach).

Etching – Process used to aid in the bonding of fluoropolymers.

EtO – (Gas Sterilization) process to kill bacteria/germs that uses Et hylene O xide Gas.

FDA – (Food and Drug Administration) Government agency that oversees medical device law enforcement.

Flaring – Expanding the geometry of a tube. Often a cylindrical expansion to allow insertion of another tube.

French Size (French Gage) – A system of measuring catheters and other devices (developed in France) that measures the circumference of a device (written 7Fr or 8F). This system was developed when tubing manufacturing was not capable of producing round tubing. The diameter conversion of French Size is approximately 1/3 of a millimeters or .01314 of an inch (5 Fr = 5 X .01314 = .066). In some very old literature you will see French Size abbreviated as Ch. in honor of Dr. Charriere who invented the French Size system.

Gamma Sterilization – Process to kill bacteria/germs that uses Gamma Radiation.

Gas Sterilization – (EtO) Process to kill bacteria/germs that uses Ethylene Oxide Gas.

GMP – (Good Manufacturing Practices) Manufacturing regulation that finished Medical Device manufacturers are required to follow.

Heat staking – The process of imbedding the braid wires into the base coat.

Hoop strength – Hoop strength is a physical property that describes the ability of a tube to withstand internal pressure, bending and crushing forces.

Hubbing – Adding or creating a part or geometry on the end of a tube that allows a device to be connected.

Hybrid braid – A braid configuration having two or more different materials. For example a braid having both stainless steel wire and high strength fiber.

Lineal reinforcement – Strength members pulled into the braid or extrusion longitudinally.

Liner – An extruded layer that has a low coefficient of friction, useful when biopsy jaws or other devices need to be sent back-and-forth inside the tubing. FEP is a compound that is commonly used as a liner along with other compounds.

Lubricity – An extruded material that has a low coefficient of friction. FEP is an example of a compound that offers good lubricity.

Lumen – The hole(s) running through a tube (single, double, triple lumen tubing).

Number of carriers – Typically 8, 12, 16, 24, 32 or 48. Fewer carriers with the same pick rate would have a higher braid angle.

Number of ends – Number of wires spooled on each bobbin.

O.E.M. – (Original Equipment Manufacturer) a manufacturer of components or products that does not sell finished devices to the end user.

Pick rate – The number of times the braid wire crosses when counted longitudinally.

Polymer – Plastic made from several monomers. A monomer is a singular type of base plastic.

Proximal – The near end of a device (from the user’s viewpoint).

Radiopacity – Ability to be seen on an x-ray or fluoroscope (material that blocks x-rays).

Resin – Technical word for virgin or base plastic polymers.

Rotary cut – Cutting a tube to length using an automated machine where the cutting head spins around the stationary tubing. This type of cutting results in a perpendicular flush cut.

Spiral reinforcement – Reinforcing a tube by means of applying the reinforcing members in a helical method.

Stiffness – A term used to describe a tube’s flexibility. Materials with a greater flexural modulus exhibit a greater stiffness.

Straightener – A tool used to reduce curvatures in a material. In-line straighteners generally have two sets of rollers oriented 90 degrees apart from each other that the material passes through.

Tie layer – An extruded layer used to bond two extruded dissimilar materials. Typically placed between liner and topcoat.

Tipping – Adding a feature on the distal end of the tube. Typical features include tapering the end or adding softer material.

TIR – Total Indicated Runout is a measure of roundness. It is expressed as the difference between the maximum and minimum distance from the outer surface to the centerline of an object.

Variable pick – Changing the pick rate of the reinforcement along the length of the tubing. By varying the pick rate, the amount of wire and the angle at which it is assembled will also vary which will have a direct affect on the stiffness or torsional rigidity of a tube along its length. This would be particularly valuable where the distal end and the proximal end need different flexibility.

White Room – A manufacturing area in which intentional steps are being taken to minimize and control dust and germs but routine testing is not performed (same as Controlled Environment).